Ask any chef:

Cooking is an art.

Baking is a science.

Following a recipe for dinner after work or in a fine restaurant does not require strict adherence to the recipe card, in fact, within reason, deviation from the recipe card can create new and delicious discoveries.

Baking is different. Baking recipes must be followed closely because certain ingredients act as binding agents while others act as leavening agents. Deviation from a baking recipe might mean that your creation falls, is misshapen, or lacks texture.

Creating alloys is like baking. There are specific properties and additives that create strength, ductility, and resistance to heat among other properties. An alloy is a substance composed of two or more metals, or a metal and a nonmetal, intimately mixed, usually by being fused together and dissolving in each other when molten. The resulting material often has different, and often enhanced, properties compared to its individual components. When following the correct recipe, alloys create new metals with enhanced properties that are fit for a specific purpose.

Current alloys, and the pursuit of new alloys, are important to manufacturing of all sorts of goods from emerging technologies to military products. And returning manufacturing to the United States is a key goal of the Trump Administration’s ongoing tariff policies. The tariffs, in theory, are designed to incentivize consumers to buy goods manufactured in the US and for companies to move their manufacturing to the US.

But what happens if you can’t get all the ingredients for your alloy recipe at home?

One ingredient we have a hard time getting a hold of domestically is big number 39 on the periodic table. Yttrium is an interesting metal. Technically, it is not a lanthanide (or heavy REE), but a border metal. Its chemical properties are similar to the rest of the heavy REEs, so it tends to hitch a ride with its friends in the lanthanide clan listed below:

Europium (Eu)

Gadolinium (Gd)

Terbium (Tb)

Dysprosium (Dy)

Holmium (Ho)

Erbium (Er)

Thulium (Tm)

Ytterbium (Yb)

Lutetium (Lu)

Yttrium is one ingredient whose absence will make our industrial cakes topple right over. Especially those that we are building to fly or go to war. But what is the heavy REE interloper with too many consonants and why is it important to emerging technology. Get ready to open that high school chemistry book again!

In Context

In our previous article, we discussed neodymium, a light REE with applications to magnets and the extent to which China has gone to restrict its processing technology. Yttrium is critical for creating alloys for specialized applications by improving properties of the new material such as:

Strengthening Additive: Yttrium is added to aluminum and magnesium alloys to increase their strength, reduce grain size, and improve resistance to high temperatures and oxidation.

Superalloys: It is a component in some high-temperature superalloys used in jet engines and gas turbines due to its ability to enhance high-temperature strength and corrosion resistance.

Heating Element Alloys: Yttrium is used in certain alloys for heating elements due to its high melting point and resistance to oxidation at high temperatures.

Deoxidizer and Grain Refiner: In metallurgy, yttrium acts as a deoxidizing, desulfurizing, and denitrifying agent in various metal alloys, improving their overall quality. It also functions as a grain refiner, controlling the microstructure for enhanced mechanical properties.

Think of Yttrium as one of the ingredients in our baking recipe, without which our cake will lack several important properties. But before we get into grain refining (and we will), a less than pretty picture.

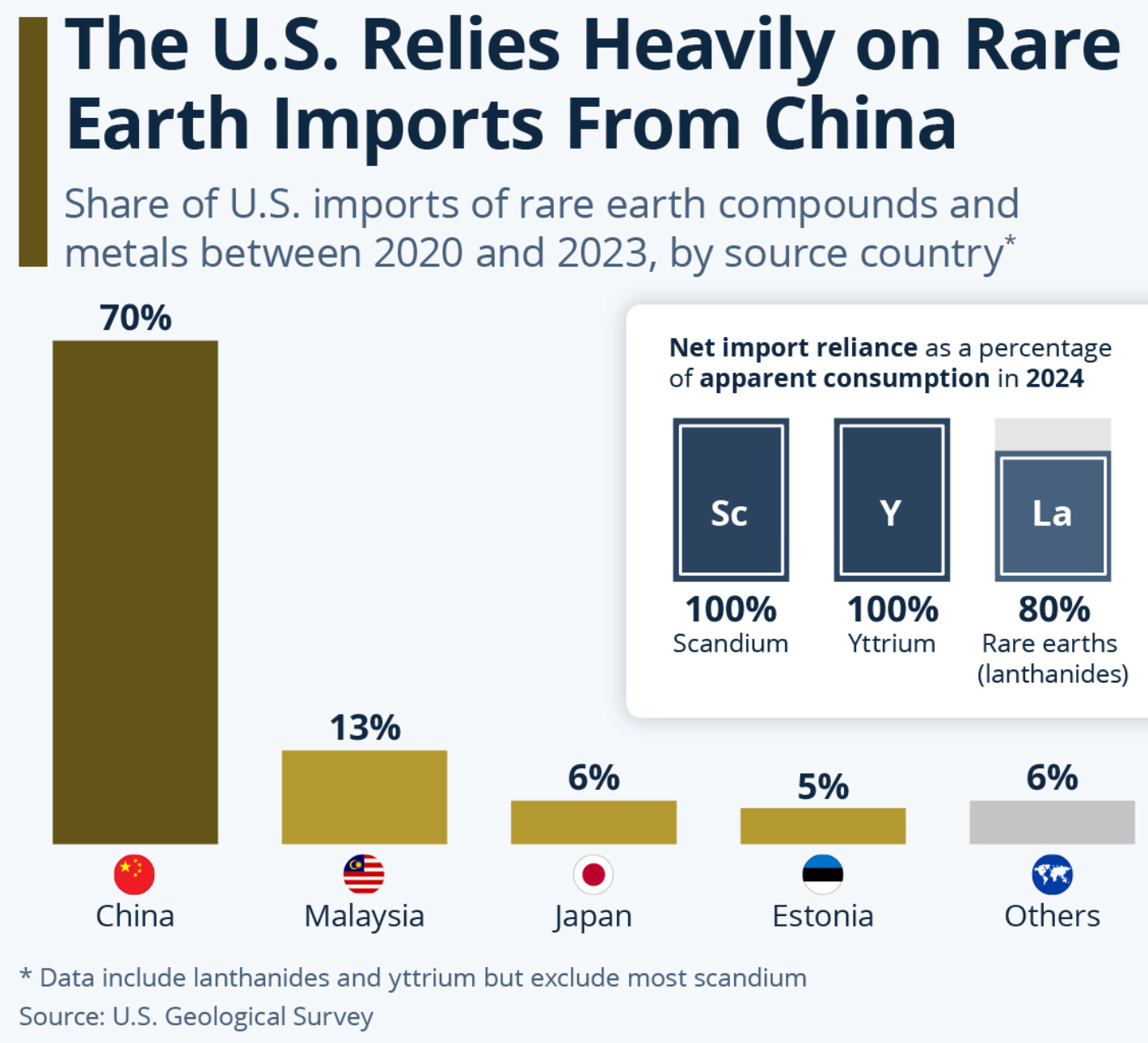

According to a 2024 Statista report, as a percentage of net consumption, the US was 100% reliant on China for imports of Yttrium between 2020 and 2023. 100%. The big bar to the left, at a staggering 70%, is the percentage of all REEs the US imports from China, but Yttrium alone stands at 100.

The US lacks the natural deposits and mining capabilities to make up this gap for Yttrium (and most other heavy REEs), but the deposits only tell part of the story.

The real gap is in the refining and processing of Yttrium, which China heavily dominates in terms of facilities, technology, and skilled workforce. This dominance is the result of a long-term vision that was expertly executed to invest in REE extraction, and especially processing, and to restrict those processing technologies from export. Today, China enjoys a global monopoly on Yttrium to one of its biggest consumers, the US.

The trade war has amplified this issue but certainly did not start it. The Chinese were already exercising global dominance and restricting technology from the rest of the world decades before Trump’s trade war. Now, the US may find itself without a critical raw material that is required for multiple applications in manufacturing. China found a geopolitical level and is pulling it. The problem is not that the US needs to build Yttrium refining facilities or mine for Yttrium domestically. The problem is that it has neither the domestic deposits, technical expertise, nor processing technology to compete with China even if it was given two decades to do so. This leaves the US almost entirely dependent on Chinese Yttrium as shown in the Statista graphic.

If the US wants to bake with Yttrium, and it does, we need to understand why it is so important so we can find ways to secure our supply of Yttrium and design a trade policy that does not leave it without critical ingredients required to bake the world’s best emerging technologies.

Getting Granular

If I start talking about “grain size” you might think that I’ve taken the food analogy too far. I’ve certainly been known to take analogies to their bitter end, but grain size is part of why Yttrium is so important. Specifically, Yttrium reduces the grain size in critical alloys when it is mixed into the recipe.

In the creation of alloys, grain size refers to the average size of the individual crystals, known as grains or crystallites, within the solid metallic structure. Most metals and alloys are polycrystalline, meaning they are composed of many small crystals joined together at boundaries called grain boundaries.

Imagine mixing multiple different metals in a pot. All of the metals are in a liquid state. If you get the recipe right, the metals will solidify into something completely different. What they solidify into depends heavily on what you need them for. For example, you might need an alloy that can withstand high temperatures. Perhaps you need one that bends and flexes rather than breaks. Or maybe you need one that is stronger than typical metals. Whether or not you get these characteristics in your new alloy will in large part depend on your grain size.

Here’s how the process works:

Crystallization: When an alloy solidifies from a molten state, atoms arrange themselves into ordered, repeating three-dimensional patterns called crystal lattices. Multiple nucleation points occur throughout the liquid metal, and these initial crystals grow until they impinge upon each other, forming grain boundaries.

Grains: Each individual crystal within the solidified alloy is a grain. Within a single grain, the crystal lattice has a consistent orientation. However, the orientation of the lattice changes from one grain to the next across the grain boundary.

Grain Boundaries: These are interfaces between the individual grains where the crystal structures of adjacent grains meet at different orientations. Atoms at grain boundaries are not as regularly arranged as those within the grains, leading to a higher energy state in these regions.

Size Measurement: Grain size is typically reported as an average grain diameter or by a grain size number (often using the ASTM E112 standard). A higher grain size number indicates smaller grains.

The grain size of an alloy significantly influences its mechanical properties. Those properties determine whether an alloy will hold up under harsh conditions for its intended purpose. Controlling the grain size in an alloy means making the grains larger or smaller, both of which have implications on different properties:

Strength and Hardness: Generally, smaller grain sizes lead to increased strength and hardness. This is because grain boundaries act as obstacles to the movement of dislocations, which are line defects in the crystal lattice responsible for plastic deformation (the ability of a material to permanently deform without breaking). More grain boundaries in a finer-grained material mean dislocations have shorter distances to travel before being impeded, making it harder for the material to deform.

Ductility: Generally, for a given alloy, larger grain sizes tend to increase ductility. This is because fewer grain boundaries allow for easier deformation within individual grains. However, very coarse grains can sometimes lead to reduced formability and surface roughness (orange peel effect) during deformation.

Toughness: Finer grain sizes can also improve toughness, especially at lower temperatures, as they can lower the ductile-to-brittle transition temperature.

There are various reasons why the grain size in an alloy would need to be smaller or larger. However, Yttrium is a key ingredient to reducing grain sizes in alloys when combined with other techniques such as controlled cooling rates. Access to Yttrium helps ensure alloys with increased strength and hardness and the applications of this additive are critical for our ongoing emerging technology dominance.

Applications

Talking about grain size might seem overly…ahem…granular, but it is akin to talking about binding agents in baking. Seemingly unimportant if all you are interested in is eating the cake but the absence of which would leave you with a mess. Here are some of the industrial applications that require small grain sizes in alloys:

Aerospace Components: In aircraft and spacecraft, alloys used for fuselage structures, wing components, landing gear, and engine parts require high strength and fatigue resistance while minimizing weight. Smaller grain sizes in aluminum, titanium, and steel alloys significantly improve these properties, allowing for thinner and lighter designs without compromising structural integrity.

Automotive Components: Similar to aerospace, the automotive industry benefits from high-strength, lightweight alloys with fine grain structures for chassis components, suspension parts, and safety-critical elements. This contributes to fuel efficiency and crashworthiness.

High-Pressure Vessels and Piping: In chemical processing plants and power generation facilities, alloys used for vessels and piping that withstand high pressures and temperatures need exceptional strength and creep resistance. Finer grain sizes can enhance these properties, ensuring safe and long-lasting operation.

Fasteners (Bolts, Screws, Rivets): Small grain sizes in the alloys used to manufacture high-strength fasteners are essential to ensure they can withstand significant loads without yielding or fracturing, maintaining the integrity of assembled structures.

Rotating Machinery (Turbine Blades, Shafts): Components subjected to cyclic loading, such as turbine blades in jet engines and power turbines, as well as rotating shafts in various machinery, benefit significantly from finer grain sizes. Smaller grains hinder crack initiation and propagation, leading to improved fatigue life and reduced risk of failure.

Springs and Flexures: Alloys used in springs and flexures that undergo repeated bending or stretching need high fatigue strength. A fine grain structure enhances their ability to withstand these cyclic stresses over a long period.

Gears and Bearings: In applications where surfaces are in constant contact and experience friction, a finer grain size in the alloy can lead to improved wear resistance. The increased number of grain boundaries can impede the movement of dislocations responsible for wear.

A World without Y

Beyond refining grains in alloys, Yttrium also has applications in phosphors, lasers, and ceramics. Along with alloys, these are some of the baseline materials required for manufacturing everything from military hardware to green technology to medical devices. If the US hopes to bring back manufacturing to its homeland, it needs to start by defining what it wants to manufacture. If the goal is to bring in manufacturing of technologically advanced and globally valuable products, US decision makers need to understand the fundamental requirements of a manufacturing base. Manufacturing from textiles to aerospace requires raw materials. Geopolitically, the dominance of emerging technologies is not debated as we see countries around the world put resources and treasure behind building capacity in technologies such as AI, quantum, space, telecommunications, and more. The requirements for military hardware are not waning either. The idea to bring critical manufacturing onshore is, in some cases, a good idea that will help the economic and national security of the US. However, all the factories in the world cannot even begin production if they don’t have the basic materials required.

Yttrium is an additive, a minor sounding ingredient on the recipe card. Aluminum and magnesium can still be produced without Yttrium, but their quality will suffer at the atomic level. Yttrium is part of what lets us refine the crystal lattice grains to create alloys that are stronger, more heat resistant, and high fatigue resistance. Those are characteristics that are quite important in military and aerospace applications but also for automotive and green energy technologies. Building the best in the world means ensuring the basic structural components are also the best in the world and that requires refining grain sizes in the alloys that they are made of.

Yttrium is just one of multiple REEs over which China exercises an effective dominance. In fact, nearly all heavy REEs are dominated by China. While substitutes may be identified for one REE or small quantities of REEs, replacing the entire US domestic consumption of REEs without China comes down to two choices:

Engineer around it (i.e. create new methods for producing the same quality products)

Make a deal with China

China’s lead in Yttrium extracting, refining, and processing has resulted in a total US dependence. We cannot hide from the raw materials required to bring back high tech manufacturing. We should begin by understanding what REEs we need and why. Next, we need to understand the REE value chain and where it can and cannot be changed. Ensuring the supply of raw materials needs to be a goal. China already knows it, which is why they are (and have been for some time) using raw materials as geopolitical leverage. But making a deal with China doesn’t necessarily mean “capitulation.” It means exercising some healthy realism and defining clear goals. Saying the US “will bring back manufacturing” is not sufficient. We need to say what manufacturing and detail what is required to do so. Raw materials should be high on that list.

Yttrium might be unfamiliar and sound funny to say, but we need it. And we can’t ignore it just because it’s not a key component of our smart phones.

Oh wait, yes it is.